For my EW/MW Panzer Company, I picked up the newly-released Panzer III F/G/H kit from Plastic Soldier Company from The War Store. Overall, this was a nice kit to build but it IS time-consuming (especially after assembling Zvezda's 1/100 models the past few days) and there are some flaws to be aware of.

For my EW/MW Panzer Company, I picked up the newly-released Panzer III F/G/H kit from Plastic Soldier Company from The War Store. Overall, this was a nice kit to build but it IS time-consuming (especially after assembling Zvezda's 1/100 models the past few days) and there are some flaws to be aware of.To start off, as always, Plastic Soldier Company's box art and design is really great. I reviewed one of their early kits last year (the Russian T-34s) and the box art was just OK but it seems like they're really starting to do some nice, evocative scenes on their boxes. This may not be a big deal for some modellers but it is to me and I'm sure it can be a nice merchandising point for retailers.

Additionally, I've noticed that PSC is one of the very few plastic kit makers who utilize ALL of their packaging. You can see below that the sprues are really packed in well and there is no wasted space, which means less packaging waste.

Each kit comes with 5 tank sprues and instructions. The instructions and sprues aren't bad, but I think PSC really needs to start investing some time into parts numbering and more detailed instructions. Even with 15 years of model-building under my belt, I had a tough time discerning what the plain plastic rectangle pictured as being inserted in the rear of the chassis was (...it's the muffler, if you're curious, which I only found out through looking at the rear of the assembled model pic in the bottom of the instruction sheet).

Each kit comes with 5 tank sprues and instructions. The instructions and sprues aren't bad, but I think PSC really needs to start investing some time into parts numbering and more detailed instructions. Even with 15 years of model-building under my belt, I had a tough time discerning what the plain plastic rectangle pictured as being inserted in the rear of the chassis was (...it's the muffler, if you're curious, which I only found out through looking at the rear of the assembled model pic in the bottom of the instruction sheet).

This lack of numbered parts combined with a very basic instruction sheet could make putting this kit together properly very difficult for amateurs. As I mentioned last year in the T-34 review, I recommend going over the instructions thoroughly and dry-fitting all parts before fitting.

Moving on, the first sub-assembly was the turret. It's an easy enough process but there is one very big, even glaring, flaw - there is a large, noticeable casting void on the G/H model turret gun (see below). It wouldn't be such an issue if this were on the bottom of the gun, but sadly it's not.

This will obviously need to be filled before painting. Again, not an issue for a seasoned modeler but might be tough for a newcomer. Another problem is the KWK barrel is very thin and easily breakable and I'll give you a tip:

When cutting either turret gun from the sprue, CUT THE FRONT BARREL SPRUE FIRST, then cut the two holding the elevation plate.

If you try cutting the elevation plate sprues first, it will cause too much stress on the barrel, which may cause it to snap or bend. Otherwise, the turret sub-assembly is straightforward.

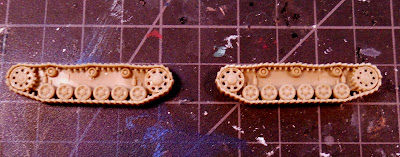

The second sub-assembly are the left and right tracks and, again, we run into another issue involving the casting problems. In the pic below, I've started to scrap down the roadwheels in the foreground (so you can see they are even) while I left the roadwheels in back as they come off the sprue. Can you tell the difference?

The problem is there's a slight ridge on the side which attaches to the chassis so, if you don't scrap or sand this down, it will cause the tracks to bow inwards and not be level. This can be very time-consuming and added somewhere between 5-10mins to each tank build.

The last assembly is the chassis build and then putting the tracks and turret on. The chassis assembly is the easiest one of the three and the main chassis has enough room inside to add a little or a lot of weight, if you're so inclined (I added about an ounce worth of lead). I should note that, when attaching the tracks, don't push them all the way up (they can easily hit the fenders, even though PSC put "pegs" on the chassis sides to "prevent" this). Instead, there's a slight lip on the back of each track that should end up sitting proud of the chassis bottom.

Below is a completed Ausf. G model.

Luckily, I have a Battlefront StuiG33b (which is an assault gun based on the PzIII chassis) to compare it to. As you can see below, both models are nearly identical in size and scale. The PSC model is only slightly longer but, being less than a 1mm difference, is virtually undetectable on the tabletop.

Pros:

-Lots of good, accurate detail

-Scales well with other Battlefront FOW armored vehicles

-Deep chassis interior allows you to add weight

-Price point is a huge savings over every other 15mm producer

Cons:

-Very prominent casting void in KWK38 gun needs to be filled

-KWK38 gun is easily breakable

-Raised areas on road wheels can make track assembly time-consuming

-Lack of parts numbering, basic instructions, and casting defects can make this a difficult build for newcomers

3 comments:

Great review. Unfortunately my old eyes cant see exactly what you did with the road wheels. Did you bevel them at a 45 degree?

@Max: No worries, it's really tough to see unless you view it firsthand.

Basically, there's a .5mm area on the roadwheels that is slightly raised above the surface of the others. This required me to scrape down the ridge with the edge of an X-acto blade and then sand the roadwheels smooth.

Had I simply glued the tracks unto the roadwheels as is, the tracks wouldn't sit evenly.

Sweet.... waitign for Andrew over at Sergeant Major to get in soem Panthers and then I'll have him ship me the PZ III as well. Going to do them as late 1941 2nd SS to support my SS infantry. Looking forward to see hwo you paint them up.

Post a Comment